Working with a leader in the automation industry, EIS Wire & Cable was tasked to design the next generation of instrument and control tray cables. These new cables would need to fit a “one cable fits all” solution to the growing list of applications and agency approval demands for ITC/PLTC type cables.

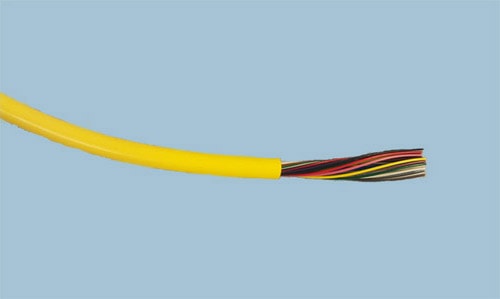

Using our wire extrusion, cable core twisting and shielding/jacket extrusion capabilities, we produced .413″ diameter, 11/C 18AWG cables and .394″ diameter 19/C composite cables that are both dual rated and can be used for instrument or control cable. All had a yellow PVC jacket and were manufactured with an extremely round and smooth surface for ease of molding connectors to the cable.

Withstanding temperatures up to 105°C, the cables feature 300 V and 600 V capacity and are resistant to sunlight and water.

These enhanced shielded and unshielded cables were granted a variety of agency approvals which allowed our customer greater flexibility in offering products to the marketplace that cover a multitude of approvals in one cord design. For more information on this development and manufacture of an instrument and control tray cable project, please see the table below.